Choosing Between Standard and Custom Manufacturing Services in Utah: A Buyer's Guide

When sourcing manufacturing services in Utah, businesses often face the choice between standard and custom solutions. Each option has its advantages, and the right choice largely depends on your specific needs and goals. This guide will help you navigate these options to make an informed decision.

Understanding Standard Manufacturing Services

Standard manufacturing services refer to mass-produced items that follow a set specification. These services are typically more cost-effective due to economies of scale, making them a popular choice for companies looking to minimize expenses. They are ideal for products where customization is not a priority and where consistency and reliability are essential.

Benefits of Standard Manufacturing

The primary advantage of standard manufacturing is its cost-effectiveness. Since products are produced in large quantities, the cost per unit is lower. Additionally, standard manufacturing offers quick turnaround times, as processes are streamlined and optimized for efficiency. This can be a crucial factor for businesses with tight deadlines.

Exploring Custom Manufacturing Services

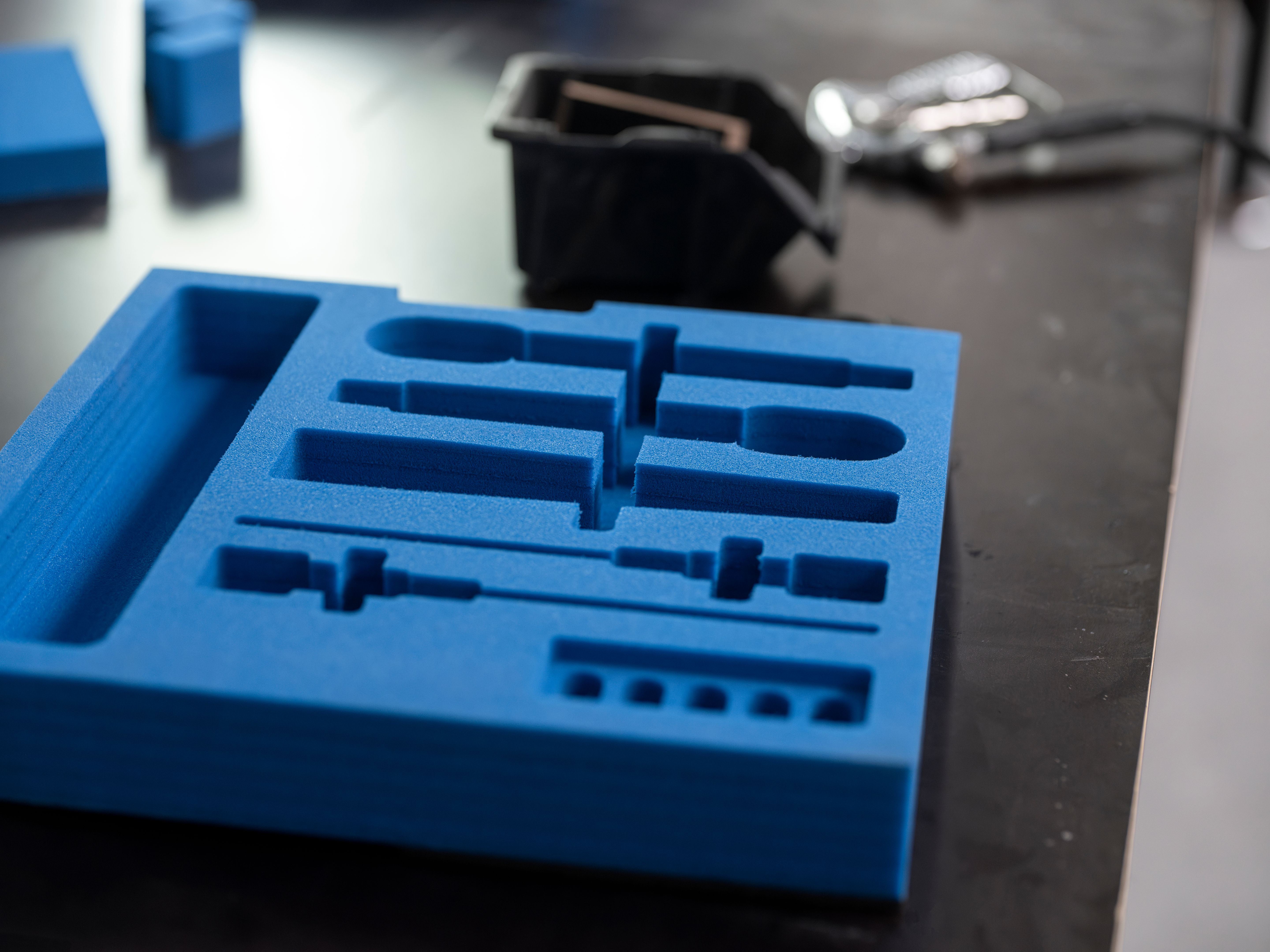

Custom manufacturing services provide tailored solutions to meet specific client requirements. This option is ideal for businesses that need unique products or components that aren't available off the shelf. Custom manufacturing can involve specialized designs, materials, and processes to achieve the desired outcome.

Advantages of Custom Manufacturing

One of the key benefits of custom manufacturing is the ability to create a product that perfectly fits your needs. Whether it’s a unique design or specific material requirements, custom solutions offer flexibility and innovation. This approach can significantly enhance product value and brand differentiation, helping your business stand out in a competitive market.

Custom manufacturing also allows for better quality control. Since products are made to order, there is more oversight in the production process, ensuring that the end product meets your exact specifications.

Factors to Consider When Choosing

When deciding between standard and custom manufacturing, consider the following factors:

- Budget: Determine your budget constraints and whether cost savings or product uniqueness is more critical for your business.

- Timeframe: Assess your timeline to see if the faster delivery of standard products meets your needs or if you can afford the longer lead times often associated with custom solutions.

- Product Requirements: Consider the complexity and uniqueness of your product to decide if custom features are necessary.

- Volume: Analyze the quantity needed and whether a mass-produced product can suffice or if specific customization is essential.

Making the Final Decision

The choice between standard and custom manufacturing services ultimately boils down to your specific business needs. Evaluate your priorities, whether they are cost, speed, uniqueness, or quality, and choose a partner in Utah that aligns with these objectives. By understanding the differences and benefits of each option, you can make a decision that supports your business goals and drives success.